Refiners typically assay precious metal scrap by means of x-ray fluorescence spectroscopy.

This entails melting the precious metal scrap in a furnace and taking a 2-3g sample via vacuum pin tube.

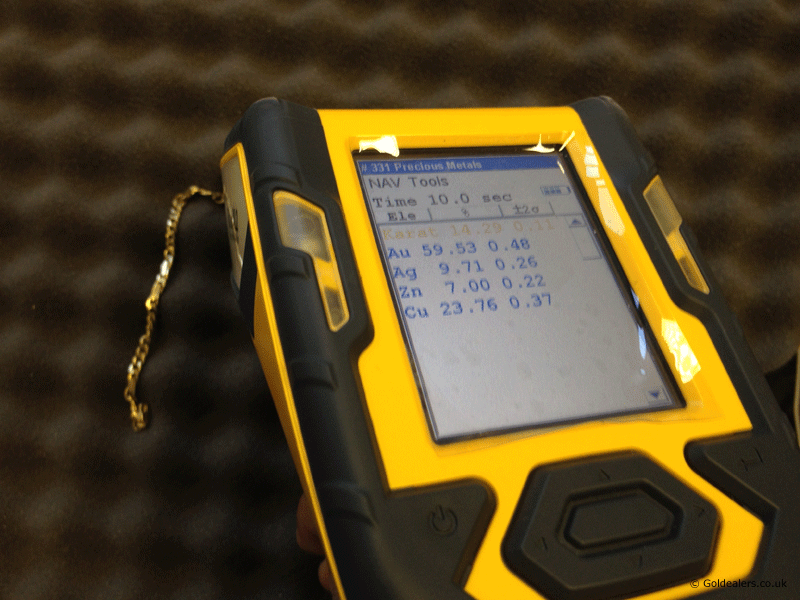

Following this, x-ray technology is used to determine the composition of the sample at the atomic level.

Whilst not as accurate as fire-assay, XRF technology can obtain accuracies of within 10 Parts per Thousand of an Assay office Reading.

There are many manufacturers of XRF spectrometers. The most well known and respected of which include Bruker, Thermo Scientific Niton, Oxford Instruments and Olympus.

The detectors are in essence a type of geiger counter, in that they count x-rays, however more complex because they are also required to classify the energy levels of the x-rays detected.

XRF-Spectrometers have an extremely high cost, primarily due to the x-ray detector technology used. Two typical x-ray detectors include Si-Pin and Si-Drift. Spectrometers with Si-Pin detectors typically cost upwards of £16,000 and those with Si-Drift detectors upwards of £20,000.

This is because Si-Drift detectors are able to work significantly faster, and with a higher resolution than Si-Pin detectors. The Si-Drift detectors can measure the entire spectrum simultaneously.